The history and development of DEBA Fasteners based on Cold Forming

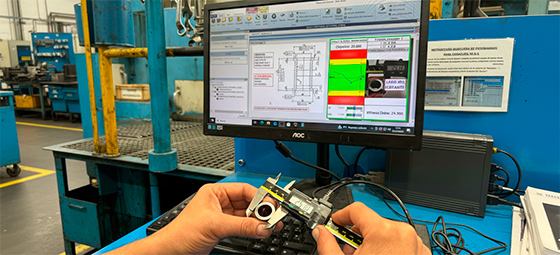

In 2024, we implement shop-floor data capture using Mitutoyo’s Measurlink software, allowing us to control, analyze, and ensure full traceability of all measurements taken by operators on each machine, guaranteeing the quality and precision of the production process.

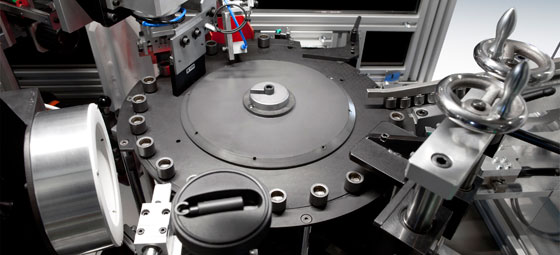

In 2014 we began to transform our business model, a process which is on-going, and whose objective is to orient ourselves towards high added value customers. The objective is for Tornillería DEBA Fasteners to take a real leap forward, becoming a development company for designing solutions based on each customer’s ideas. We have made firm commitment to orientating our production capacity towards more technical parts.

In 2007, as a consequence of our business growth, we moved to a 8,800 m² factory, which enables us to adapt our installations to cope with the market’s increasingly high requisites, increasing our flexibility and production capacity, while also improving our personnel’s work conditions. We do all of this respecting our commitment to the environment.